With the advent of laser technology, engraving has reached new heights of precision and versatility. Engraving has long been revered as a timeless art form, adding a touch of personalization and sophistication to various objects. But what about its permanence?

In this blog, we delve into the question: Is laser engraving permanent? We explore the laser engraving process, the factors influencing its permanence, techniques to maximize longevity, and even compare laser engraving with alternative methods.

Whether you’re considering laser engraving for personal or professional purposes, understanding the permanence of the engravings is essential.

What Is Laser Engraving?

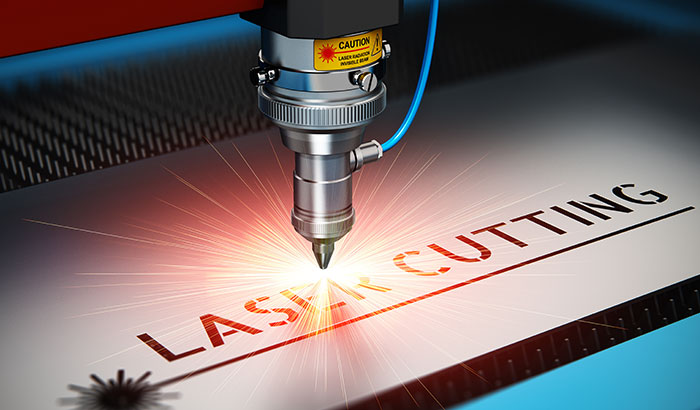

Laser engraving is a highly precise and versatile technique that involves using a focused laser beam to etch designs, patterns, or text onto a wide range of materials. The laser beam is directed onto the surface of the material, where it interacts with the atoms or molecules, causing them to undergo a physical or chemical change. This change creates visually striking engravings.

The laser beam generates heat as it interacts with the material, causing it to either melt or vaporize. The depth and intensity of the engraving can be controlled by adjusting the laser’s power, speed, and focus. This control ensures that the engraved marks are clear, precise, and long-lasting.

By grasping the intricacies of the laser engraving process, the types of lasers used, and the selection of suitable materials, one can gain a deeper understanding of how engraving permanence is achieved. This knowledge empowers individuals and businesses to make informed decisions when it comes to personalized engravings, ensuring that the results meet their expectations for durability and visual impact.

The Laser Engraving Process

The laser engraving process begins with a high-powered laser beam that is emitted from a laser engraving machine. This concentrated beam of light is controlled by computer software, which directs it to trace the desired design onto the material’s surface.

As the laser beam hits the material, it heats and vaporizes or melts the surface layer, creating a cavity or groove. The depth of the engraving is determined by the intensity and duration of the laser beam’s exposure to the material. The precision and accuracy of the process allow for intricate and detailed engravings.

Several types of lasers are commonly used for engraving, each with its unique characteristics and applications. Here are the main types:

- CO2 Lasers: Carbon dioxide (CO2) lasers are widely used in engraving due to their versatility and ability to engrave a wide range of materials. These lasers emit a high-powered infrared laser beam that is highly absorbed by organic materials, such as wood, leather, paper, acrylic, and certain plastics.

- Fiber Lasers: Fiber lasers are known for their exceptional precision and speed. They are primarily used for metal engraving, including stainless steel, aluminum, brass, and other metals. Fiber lasers generate a concentrated beam through the use of optical fibers and are particularly effective for marking serial numbers, barcodes, or intricate designs on metal surfaces.

- Nd:YAG Lasers: Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers are commonly used for deep engraving on hard materials, including metals, ceramics, and glass. These lasers generate a high-energy pulsed beam that can remove layers of material, resulting in deep, long-lasting engravings.

What Can Be Laser Engraved?

Laser engraving is compatible with various materials, each offering different results and permanence. Some of the most commonly used materials include:

- Wood: Laser engraving on wood creates a beautiful and permanent mark. Hardwoods like maple, oak, and cherry yield excellent results, as the engraving penetrates the surface and creates a lasting impression.

- Acrylic: Acrylic is a popular material for laser engraving due to its transparency and versatility. The laser beam can create precise and detailed engravings, resulting in a permanent mark on the acrylic surface.

- Leather: Laser engraving on leather offers a distinct and elegant look. The laser beam interacts with the leather’s surface, creating contrasting tones and a long-lasting engraving.

- Metal: Different types of metals, such as stainless steel, aluminum, and brass, can be engraved using lasers. The laser removes the surface layer, creating a permanent mark that is highly resistant to fading or wearing off.

- Glass: To laser engrave on glass produces a frosted or etched effect. While the engraving may not be as deep as on other materials, it can still be relatively permanent if handled and maintained properly.

It’s important to note that the suitability of a material for laser engraving may depend on various factors, including its composition, thickness, and surface finish. It’s advisable to consult with experts or conduct tests to determine the best results for specific materials.

Is Laser Engraving Permanent?

Laser engraving offers remarkable durability, but several factors can influence the permanence of the engravings. Understanding these factors is crucial to ensure long-lasting results.

Depth and intensity of the engraving:

The depth and intensity of the engraving play a significant role in determining its permanence. Engravings that are shallow or lack sufficient intensity may be more prone to fading or wearing off over time. Deeper engravings tend to provide greater longevity as they penetrate further into the material, making them more resistant to external forces.

The settings on the laser engraving machine, such as power and speed, directly impact the depth and intensity of the engraving. Achieving the right balance is essential to create a deep and well-defined mark without causing excessive damage to the material.

Material composition and properties:

The material being engraved is a crucial factor in determining the permanence of laser engravings. Different materials have varying levels of resistance to fading, scratching, or deterioration over time. Some materials, such as metals and certain plastics, are generally more durable and can withstand environmental factors better than others.

Materials with porous surfaces, like wood or leather, may absorb moisture or dirt over time, potentially affecting the appearance and permanence of the engraving. On the other hand, when you laser engrave on glass or other non-porous materials, the engraving tends to be more resistant to external factors, offering greater permanence.

When choosing a material for laser engraving, it is important to consider its composition, density, and specific properties. Consulting with experts or conducting tests on different materials can help identify the best options for achieving long-lasting engravings.

Environmental factor:

The environment in which laser-engraved items are displayed or used can have a significant impact on their permanence. Exposure to sunlight, moisture, extreme temperatures, or high humidity levels can accelerate the degradation of the engravings.

Direct and prolonged exposure to sunlight can cause fading or discoloration over time, especially in materials that are not UV-resistant. Moisture, on the other hand, can lead to corrosion, mold, or warping, particularly in materials like wood or paper. It is advisable to protect laser-engraved items from these environmental factors whenever possible.

If the engraved item will be exposed to harsh conditions or used outdoors, applying a protective coating or sealant can help enhance its resistance to fading, moisture, and other environmental factors. Regular maintenance and cleaning can also contribute to preserving the engraving’s appearance and longevity.

Wear and tear over time:

As with any surface or object, laser engravings may experience wear and tear over time, especially in items subject to frequent handling or use. The repetitive friction, impact, or contact with other surfaces can gradually diminish the clarity and depth of the engraving.

To minimize wear and tear, it is advisable to handle laser-engraved items with care, avoid abrasive cleaning methods, and store them in protective cases or covers when not in use. Regular maintenance, such as gentle cleaning and periodic inspections, can help identify and address any signs of deterioration at an early stage.

How to Maximize the Permanence of Laser Engraving

To ensure the longevity of laser engravings, several techniques can be employed. By carefully considering material choices, engraving depth and intensity, implementing protective measures, and following proper maintenance practices, you can enhance the permanence of laser-engraved items.

Choosing the right material for the intended purpose:

Selecting the appropriate material is crucial in maximizing the permanence of laser engravings. Consider the specific application and environmental conditions the item will encounter. Choose materials known for their durability and resistance to fading, such as stainless steel, hardwoods, or acrylic.

Additionally, opt for materials that are compatible with laser engraving techniques and have a suitable surface finish. Smooth surfaces tend to yield clearer and more long-lasting engravings than rough or textured surfaces.

Proper engraving depth and intensity:

Achieving the optimal engraving depth and intensity is key to enhancing permanence. Adjusting the settings on the laser engraving machine, such as power and speed, allows for control over the depth and intensity of the engraving. Aim for a balance that provides a deep and well-defined mark without compromising the integrity of the material.

Engravings that are too shallow may be more susceptible to wearing off over time, while excessively deep engravings may compromise the structural integrity of the material. Conduct tests and adjustments to determine the ideal settings for each material and application.

Implementing protective measures (coatings, sealants, etc.):

Applying protective measures can significantly enhance the permanence of laser engravings. Various coatings and sealants can be used to shield the engraved surface from external elements. For example, clear lacquer or epoxy coatings can protect against UV rays, moisture, and general wear.

These protective measures create a barrier between the engraving and the surrounding environment, preserving the sharpness, clarity, and longevity of the mark. Consult with experts or manufacturers to identify suitable coatings or sealants for the specific material being engraved.

Maintenance and care tips for laser-engraved items:

Proper maintenance and care are essential in ensuring the continued permanence of laser engravings. Here are some tips to consider:

- Avoid abrasive cleaning methods: Use gentle cleaning techniques, such as soft cloths or non-abrasive cleaning solutions, to prevent scratching or damaging the engraving.

- Store and handle with care: Protect laser-engraved items by storing them in appropriate cases or covers when not in use. Handle them with care to prevent accidental impacts or scratches.

- Avoid prolonged exposure to harsh environments: Limit exposure to direct sunlight, extreme temperatures, high humidity, or corrosive chemicals that can accelerate fading or degradation of the engraving.

- Regular inspections and maintenance: Periodically inspect engraved items for signs of wear, fading, or damage. Address any issues promptly by reapplying coatings or seeking professional assistance for restoration, if necessary.

By implementing these techniques and incorporating proper maintenance and care practices, you can significantly extend the life and legibility of laser engravings. Taking proactive measures to protect and maintain engraved items ensures that they continue to make a lasting impression for years to come.

Personalize Items With Laser Engraving from Naag Tag

When it comes to reliable and high-quality laser engraving, NaagTag is a trusted name in the industry. With our state-of-the-art technology and attention to detail, NaagTag can personalize a wide range of items, including name tags, signage, labels, and more. Our expertise ensures that your engravings will be precise, durable, and visually appealing.

Discover the possibilities of laser engraving with NaagTag. Unlock the potential to create personalized items that leave a lasting impression when you call us at 801-919-1890 or naagtag@naagtag.com.